– Scientists Successfully Transplanted 3D Printed Human Body Parts Into Rats:

Scientists are inching closer to printing a solution for the overwhelming number of people who need organ transplants, more than 123,000 in the US alone, as well as those who have lost body parts such as ears.

Bioprinting—the process of using 3D printers to create biological tissue—has been around since the 1990s, but it has previously been impossible to create structures large and stable enough to be surgically implanted. That might not be the case anymore, according to a paper published online Monday in Nature Biotechnology.

Researchers from Wake Forest Baptist Medical Center say they have developed a printer capable of printing an array of different human body parts. There’s no doubt that clinical trials are necessary before tissues created by the printer could be inserted directly into humans, but it appears that we have come much closer to printing away many of the world’s most challenging health problems. This paper represents one of the first times that bioprinted tissues, bones, and cartilage were implanted into a mammal and survived.

“We present an integrated tissue-organ printer (ITOP) that can fabricate stable, human-scale tissue constructs of any shape,” wrote the senior author of the paper, Anthony Atala, who serves as director of the Wake Forest Institute for Regenerative Medicine.

A bioprinter is essentially a 3D printer that uses cells instead of ink to “print” living tissues. The cells are harvested from stem cells or other animals, and printed along with a gel-like substance that protects them from being damaged. The gel disintegrates, and the living tissue remains. “You can print one of these structures in about 40 minutes,” Atala told me over the phone.

The beginning, middle, and end stages of printing a jaw bone structure Video: Wake Forest Institute for Regenerative Medicine

Previous bioprinting efforts were often hampered by one thing: It was too difficult to create structures that contained blood vessels, and without them, the tissues were likely to remain extremely small and fragile. The team at Wake Forest was able to overcome this by printing tiny “microchannels” which behave in a similar manner to blood vessels.

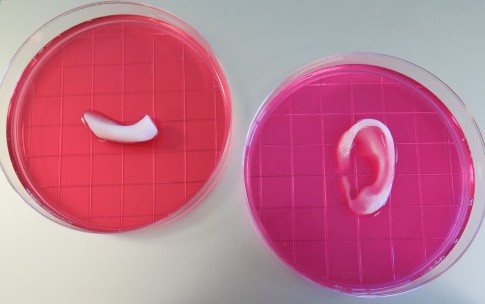

The team printed three different kinds of structures to show what their printer could do: a baby-sized human ear, muscle tissue, and a small part of human jaw bone, all of which were implanted under the skin of mice and rats. After a short period of time—between two weeks and five months—all three structures not only survived, but grew to form vascularized tissue. Similar experiments were carried out by Russian company 3D Bio, which reortedly was able to successfully implant a bioprinted thyroid gland.

According to the paper, these early results indicate that these structures could be the right size and strength to be implanted into humans.

An interesting aspect of the printer is that it’s capable of creating custom solutions for each patient. The medical scientists at Wake Forest used clinical imaging data, from things like MRI and CT scans, to create 3D computer models which show where tissue is missing in a patient, allowing the printer to create a custom piece of flesh.Atala told me that we’re most likely extremely far off from being able to print something like a finger, but that it might be possible to say, print skin in order to help a burn patient within the next decade.

Bioprinting has the potential to help those who are injured or in need of an organ, but there are also people interested in using the technology to enhance the human body, to print things like “electricity-generating superorgans.”

The technology could also lessen cosmetics companies’ reliance on animal testing, because new products could instead be tested on bioprinted flesh. Last year for example, cosmetics manufacturer L’Oréal partnered with Organovo, a bioprinting startup, to develop a testing program.

In the future, Atala and his team hope to use their printer to develop more concrete applications for humans, including creating more intricate tissues and organs. When I asked Atala if he was optimistic about the future, he said, “We definitely are. We’re doing some preclinical studies right now, and we want to take this to patients… I hate to predict, but I think that within five years this could be used in patients.”